Our fibre stars:Sustainability in the fabric

The high quality and durability of our fabrics already contribute to sustainability. Because the longer a product life cycle is, the better it is for the environment.

INDICATORS

> GRI 102-9

Our starting point is the end result: Fabric with bespoke features – exactly how our customers want it. The best possible basis for hard-wearing workwear or durable bed linen, always in the usual quality and exactly the same colour.

We exclusively process high-quality raw fabric made of long-staple fibre materials, whether cotton, polyester or lyocell. This is because the high quality and durability of our fabrics already contribute to sustainability. The longer a product life cycle is, the better it is for the environment. Our fibre stars show that sustainability starts right at the front of the value chain: During fibre production.

> GRI 102-9

Cotton

The cotton fibre has many positive properties. These include good moisture absorption and a soft, cool feel. As a natural fibre, cotton is by nature a renewable resource and biodegradable.

People have worn cotton for at least 5000 years. Cotton plants originated in Asia, Africa and South America. They grow best in a warm, humid climate. Today, cotton is cultivated in more than 80 countries all over the world. The leading growing countries are India and China, followed by the USA, Brazil and Pakistan.

Cotton, the thirsty fibre? Not quite … Learn more about the water consumption of the cotton plant here!

You want to know more about cotton?

You can find lots of exciting information about cotton at the → Bremen Cotton Exchange.

> GRI 102-9

> GRI 308-1

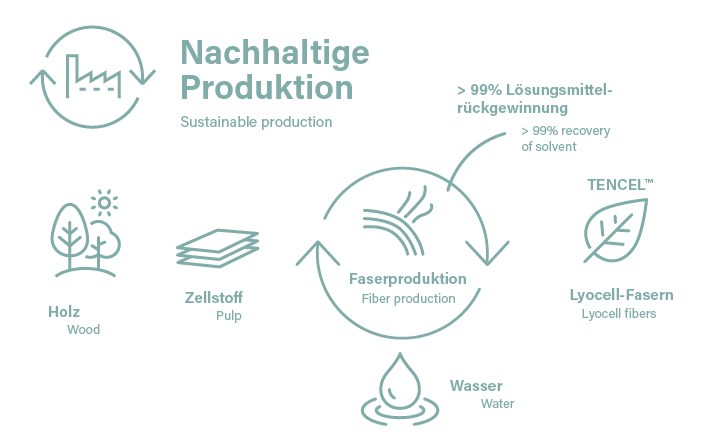

Original TENCEL™ Lyocell from Lenzing

As soft as silk, as cool as linen and as warm as pure new wool: The cellulose fibre Lyocell, better known under the brand name TENCEL™, combines many good properties. Superior absorbency, heat regulation, a cooling effect and reduced bacterial growth.

From a sustainability perspective, TENCEL™ Lyocell is also more than convincing: The fibre consists of the renewable raw material wood, artificial irrigation is not necessary and the forest areas do not compete with land used for growing food.

We only use Lyocell fibres of the TENCEL™ brand from Lenzing. The Austrian-based Lenzing Group is one of the world’s leading producers of fibre pulp from wood and cellulose fibres. The company is committed to the ecologically responsible production of fibres from wood grown in sustainably managed forests and plantations. 100 per cent of the Lenzing Group’s suppliers must comply with the global Lenzing Supplier Code of Conduct. More than 99 per cent of the pulp suppliers used by the Lenzing Group are either FSC® or PEFC™-certified or are audited according to these standards. → In the Lenzing Group Sustainability Report, the company openly communicates how sustainable raw material sourcing is implemented.

Lenzing is ranked as the leading producer of wood-based cellulose fibres by the non-profit organisation Canopy. The aim of the organisation and its ranking is to ensure that cellulose fibres from pristine and endangered forests are not processed into textiles. You can find more information about the ranking → here

External links

More than 99%

of the suppliers are certified according to a recognised standard for sustainable forestry.

You want to know more about TENCEL™?

A lot of exciting information about lyocell fibre TENCEL™ can be found at the manufacturer → Lenzing.

> EMAS

> GRI 102-9

> GRI 301-2

> GRI 308-1

Recycled polyester: Original REPREVE® from Unifi

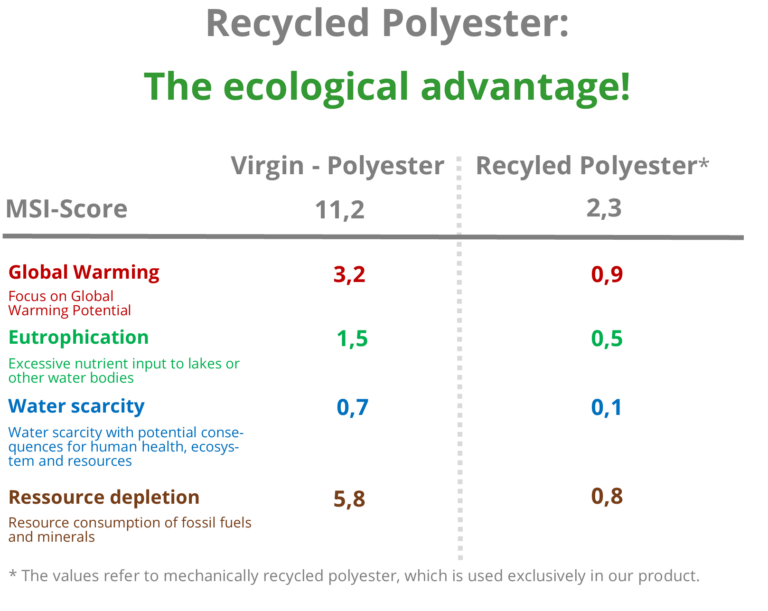

Recycled polyester is more environmentally friendly and conserves more resources than so-called virgin polyester. The recycled polyester is obtained either from waste stemming from production processes (pre-consumer waste) or from consumer waste (post-consumer waste), for example, PET beverage bottles. The ecological advantage of recycled polyester is made clear by the Higg Materials Sustainability Index (MSI for short).

We only use recycled polyester of the REPREVE® brand from Unifi. Unifi is one of the leading manufacturers of recycled polyester and sets new standards with its REPREVE® brand. Mechanical recycling makes the fibre produced more environmentally friendly than virgin polyester. We have the authenticity of the goods ensured by an additional inspection at Unifi.

All upstream suppliers are also certified according to the Global Recycled Standard (GRS). This ensures a transparent supply chain back to the origin of the recycled polyester. This standard contains, among other things, requirements for chemical and environmental management. Compliance with certain social standards is also checked in an annual audit.

100%

of our upstream suppliers are certified according to the Global Recycled Standard.

You want to know more about REPREVE®?

You can find lots of exciting information about REPREVE® directly at → Unifi.

Further articles on the topic

STeP by OEKO-TEX®

STeP by OEKO-TEX® STeP by OEKO-TEX® is a modular certification system for production facilities in the...

About this report

The Kettelhack Sustainability Report 2020 was prepared in accordance with the GRI Standard Option 'Core'. ...

CO2 Footprint – more than just a number!

The preparation of a carbon footprint adds an important component to the consumption figures. This is...